Safety soles

We produce fully customised safety shoes that comply with the highest European safety standards. Custom-made in one of our service centres!

the right insole for every shoe

The insole of every make of safety shoe must fulfil a number of conditions to comply with all European ESD safety standards. To do this every brand uses a different cover or material. We have everything we need inhouse to produce the matching safety insole for every brand of safety shoe.

measurement

The success of a good insole or orthopaedic shoe starts with exact measurement. To do this as accurately as possible, we have a number of methods.

We can put the feet in a plaster cast or in an impression box. We can also scan feet in 3D with the Structure sensor on iPad or with a laser scanner in one of our service centres. An additional gait analysis for an even more complete result is also a popular option.

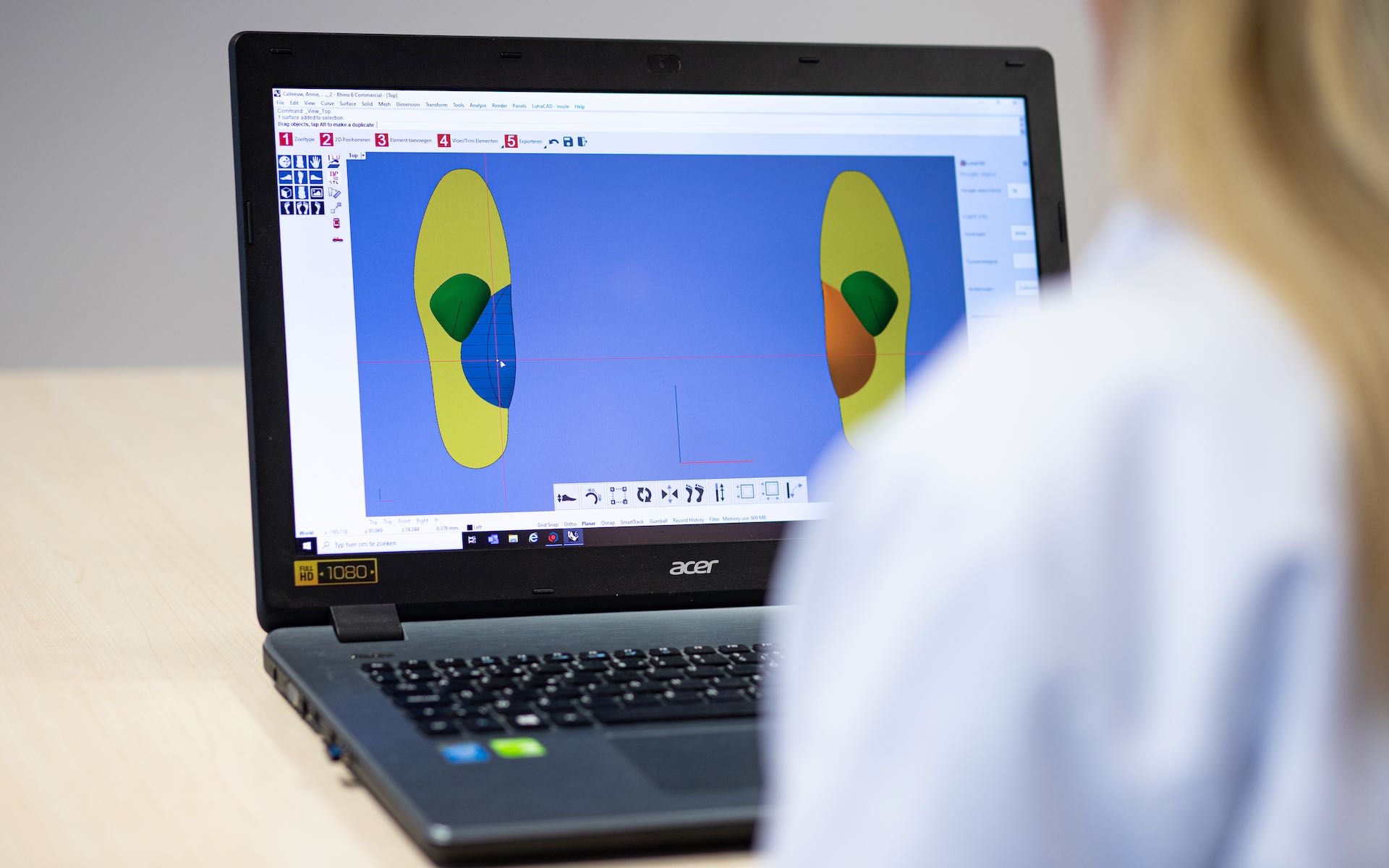

design

Our experts design the insoles in 3D using Lutracas software. These can then be milled or printed. Each area of the insole can be viewed individually and adjusted to the patient’s foot.

The final step when designing insoles is to pull the S3 standard cover for the specific shoe over the sole.

How can we help you?

Want to sit together? Or briefly clarify something over the phone? Let us know what you prefer.